How to calculate steel quantity in construction

TweetWorlds primarily building materials constitutes of steel and concrete as they have similar thermal expansion coefficient, used for the internal support and for exterior cladding in construction of buildings.

Steel and concrete go hand in hand. That which binds well stays well together. Reinforced concrete is also used to provide deep foundations and basements.

This article illustrates ways to calculate quantity of steel in slab, column and beam.

Basic data requirements for calculations of quantity of steel :

- Plan, elevation & section.

- Structural detail (slab &beam)

- All dimensions must be clear and co related.

- Type of concrete structure.

- Calculate Steel Quantity for Columns

Achieve column size and reinforcement detailing from design drawings. Then, compute quantity of steel in the column using the following steps:

Longitudinal steels

Compute total length of longitudinal bars which equal to the column height plus laps for footing multiply number of longitudinal bars.Convert that length into kilograms or Tons. This can be done by multiplying cross section area of steel by its total length by density of steel which 7850 kg/m3

Stirrups

- Compute cutting length of stirrups using the following equation

- h: column depth

- Ld.: stirrup development length

- Calculate number of stirrup by dividing column height over stirrup spacing plus one.

- Calculate total length of stirrup which is equal to stirrup cutting length times number of stirrups.

- Convert length into kilograms / Tons.

Cutting length=2*((w-cover)+(h-cover))+Ld., where

w: column width

This can be done by multiplying cross section area of steel by its total length by density of steel which 7850 kg/m3.

Total steel quantity of column equal to the sum of both main and stirrup steels.

Calculate Steel Quantity for Slab

Obtain slab dimension and reinforcement details from:- (Formulae)

- Compute number of steel bars= (Slab length(L)/spacing)+1

- Noofbars=(Slablength(S)/spacing)+1

- Calculate cutting length:

Shrinkage and Temperature Steel Bars

Cutting length= clear span(S)+Ld.+ inclined length+2×45 degree bend

Shrinkage and Temperature steel bars

Cutting length= clear span(S)+Ld.+ inclined length+2×45 degree bend, where: Ld.=development length

Inclined length can found by

Inclined length=0.45D

D=slab thickness-2*concrete cover-bar diameter

Main steel bars = No. of bars*cutting length*weight of the bar (/162)

Suppose we have a one-way slab,

which has a length 5 m or width 2 m (clear span). The Main bars will be 12 mm in diameter with 100 mm c/c spacing. The Distribution bars will be 8 mm in diameter with 125 mm c/c spacing. The Clear cover will be 25 mm (Top or Bottom) and the thickness of the slab is 150 mm.

- Calculate the quantity of steel?

- Calculate the weight of steel?

(Note the weight of the bar may vary depending upon the quality of the steel)

GIVEN DATA

Length = 5 m (5000 mm).

Width = 2 m (2000 mm).

Main Bar = 12 mm @ 100 mm c/c. Distribution Bar = 8 mm @ 125 mm c/c. Clear cover = 25 mm from (Top and Bottom). Thickness = 150 mm

SOLUTION:

THE QUANTITY IS DONE IN TWO STEPS.

STEP 1. (CALCULATION OF BARS NO'S)

First, calculate the number of bars required (main and distribution both).

FORMULA = (Total length – Clear cover)/center to center spacing + 1

Main bar

= (5000 – (25+25))/100 + 1

= 4950 Divided by 100 + 1

= 51 Bars.

Distribution bar = (2000 – (25+25))/125 + 1

= 1950 Divided by 125 + 1

= 17 Bars.

STEP 2. (CUTTING LENGTH)

MAIN BAR:

FORMULA = (L) + (2 x Ld) + (1 x 0.42D) – (2 x 1d)

# Where

L = Clear Span of the Slab

Ld = Development Length which is 40 d (where d is diameter of bar)

0.42D = Inclined length (Bend length)

1d = 45° bends (d is diameter of bar)

First calculate the length of "D".

D = (Thickness) – 2 (Clear cover at Top, BOTTOM) – Diameter of the bar.

= 150 – 2(25) -12

D = 88 mm Ans…

By putting Values.

Cutting length = 2000 + (2 x 40 x 12) + (1 x 0.42 x 88) – (2 x 1 x 12)

Cutting length = 2000 + 960 + 36.96 – 24 =2972.96 mm ~ 2973 mm or 2.973 m

DISTRIBUTION BAR:

= Clear Span + (2 x Development Length (Ld))

= 5000 + (2 x 40 x 8) = 5640 mm or 5.64 m

CONCLUSION:

Main bar:

= Numbers 51.

= Length (51 x 2.973 m) = 151.623 m.

=Weight (D^2/162) x length = 134.776 kg.

Distribution Bar:

= Numbers 17.

= Length (17 x 5.64 m) = 95.88 m.

=Weight (D^2/162) x length = 37.87.

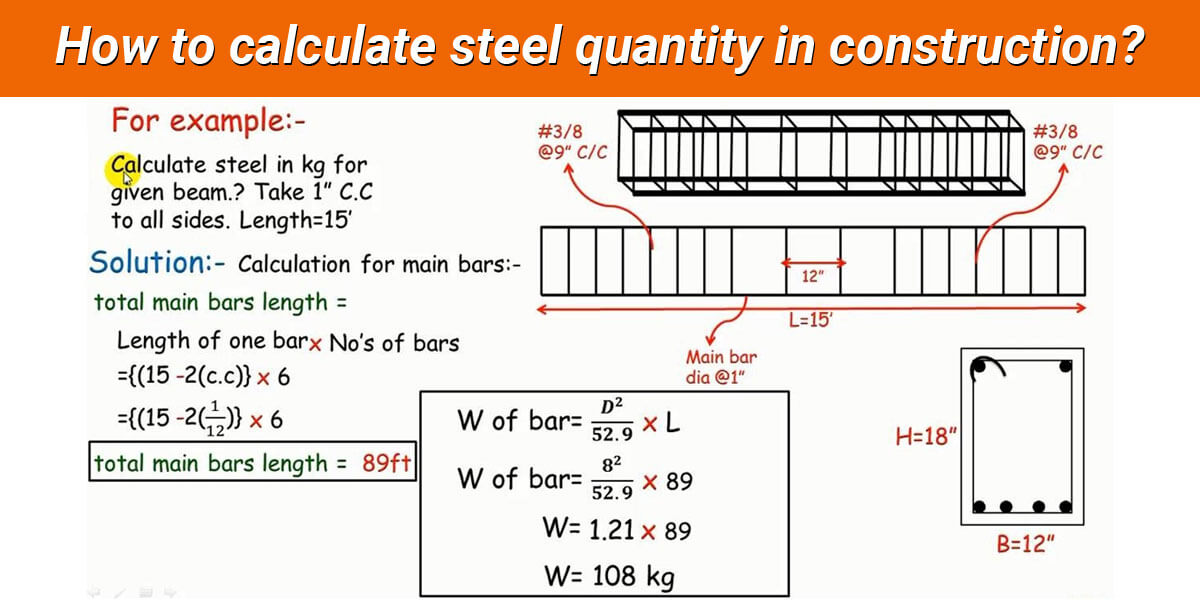

Calculate steel quantity in beam

In construction of any building the weight is most bore by the beams. Hence, stronger the beam, lasting is the construction

Therefore steel quantity in beam is always greater than other structural details.

EXAMPLE:

Let us we have a simply supported beam having a cross section 300×500 mm and length of the beam is 4 m. The main bars used in this beam is 20 mm and the support bar diameter is 16 mm. The diameter of the stirrup is 12 mm and the spacing of stirrup is at an end is 100 mm and 150 mm at the mid support of the beams.

Calculate the required quantity of steel for the beam? Cutting length of stirrups?

Calculate the weight of steel? GIVEN DATA:

Length = 4 m Height = 500 mm Width = 300 mm SOLUTION:

Main bars (20 mm):

length = length of beam + development length – bend #Where

bend 45deg=1d 90deg=2d 135deg=3d

<development length is the grip between steel and concrete >

Length:

Main = 4000 + (50d×2) – (2d×2)

= 4000 + (50×20×2) – (2×20×2)

= 4000 + 2000 – 80

=5920 mm or 5.92 m Ans..

For 2 no's

= 5.92×2

=11.84 m

Weight = d2/162 × length

=20 × 20/162 × 11.84

=29.2 kg

Supports bars (16 mm):

Length = length of beam + Ld – bend

#where <for 90 deg bend=2d>

Support = 4000 + (50d×2) – (2d×2)

= 4000 + (50×16×2) – (2×16×2)

= 4000 +1600 – 64

=5536 or 5.536 m Ans…

For 2 no's

= 5.536 × 2

=11.072 m

Weight= d2/162 × length= 16 × 16/162 × 11.072= 16.47 kg

STIRRUPS:

Length is divided into 2 way 1st is at support and 2nd is at mid support.

For end supports: (spacing 100 mm)

Length / 3 := 4000/3 = 1333.3 m

No of stirrups = Length/spacing + 1

= 1333.3/100+1

=14.33 use 15 No's

Total no of stirrups for end supports

= 15×2

= 30 No's

For mid supports: (spacing 150 mm)

Length = 1333.3 m No of stirrups

= length /spacing + 1

= 133.3/150+1

= 7.88 use 8 nos

Cutting length of stirrups:

Cross section of stirrups is Width = 300 mm

Height = 500 mm

A is horizontal length of stirrup

300 – (2 x clear cover) – (2 x half of bar dia )

= 300 – (2 x 30) – (2 x 6)

= 228 mm

B is vertical length of stirrup

= 500 – (2 x clear cover) – (2 x half of bar dia )

= 500 – (2 x 30) – (2 x 6)

= 428 mm

Cutting length of one stirrups is

Cutting length= (2 x A)+(2 x B)+(2 x 10D)-(3d x 2)-(2d x 3)

#where

<10d is hook and 3d is bend 135 for deg and 2d is bend for 90 deg>

<In one stirrups 5 bend is required>

Cutting Length:<

= (2 x 228)+(2 x 428)+(2 x 10 x 12)-(3 x 12 x 2)-(2 x 12 x 3)

= 456 + 856 + 240 – 72 – 72

= 1408 mm or 1.408 m

For total 38 stirrups

= 1.408 x 38

= 53.50 m

Weight of stirrups is= d2/162 x length

= 122/162 x 53.50

= 47.55 kg

Total weight of steel

= Main bars + Supports bars + Stirrups

= 29.2 + 16.47 + 47.55

= 93.22 kg.