The Modern Rules of Underwater Concreting Through Tremie Method

TweetWhat is Underwater Concreting

During any civil constructions where the base or the lower part of the structures is completely submerged under water that is known as underwater concrete. Underwater Concrete is mostly used in all types of Civil Engineering Construction Works.This article briefly describes the fundamentals of Underwater Concreting and the various types used to create Underwater Concreting

In Civil Constructions there comes certain situations where basements, sewerage, ducts, ports, bridges and marine works in which concrete is to be placed under water.

Utmost special care must be preserved whenever the concrete is placed underwater, it should be plastic and cohesive but have good flow capacity.The demand for the formwork is usually higher than in normal concreting under dry conditions.

This specific formwork imparts the required shape to the structure of its elements but it also must protect the concrete mix during laying until it is perfected from the direct action of current and waves. This formwork also serves a temporary protective casing, while during concentrating prevents washing out of cements and the leakage of cement mortar from the concrete mix.

Properties of Underwater Concrete

Adequate safety from corrosion can be achieved by using anti-corrosion or protecting merchandise.

Spalling of concrete can be avoided by expanding the concrete carefully.Better maintenance process includes initial inspection, worsening prediction, inspection, evaluation and remedial measures.

During construction, social as well as economic aspects are minimum along with engineering.

Performance Requirements for Underwater Concrete

- Workability & self compaction

- Cohesion against washout, segregation & laitance

- formation

- Low bleeding

- Low heat of hydration

- Controlled set time

- Compressive strength

- Adequate bond

Types of Underwater Concrete

There are discrete methods of Underwater Concrete which are described in detail.

- Tremie method.

- Toggle bags method.

- Bagged concrete method.

- Pumping technique.

- Hydro valve method.

- Tilting pallet barge method.

- Preplaced aggregate concrete.

- Pneumatic valve method.

- Skip method.

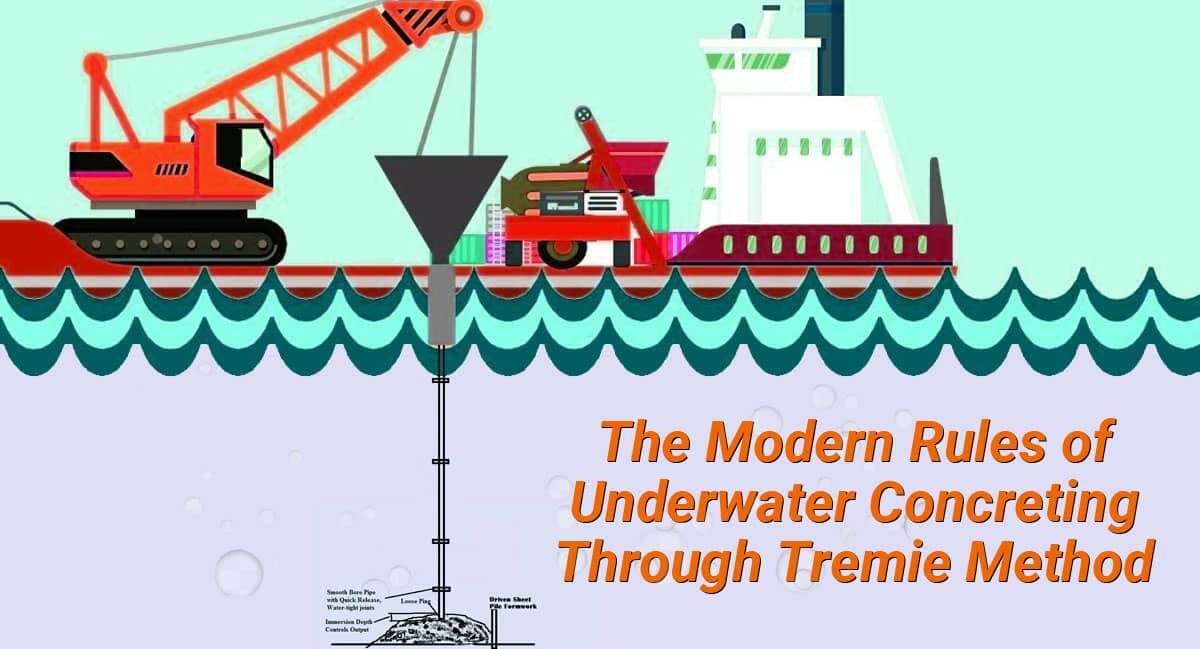

Tremie Method

Using the Tremie method a vast amount of strong flowable concrete is poured.This method is the standard method of Underwater Concreting.A Tremie is an underwater pipe generally 200 - 250 mm diameter bearing a funnel shape hooper at its upper end and a loose plug at the bottom end for discharging the liquid.The value at the discharge end enhances the control and the distribution of the concrete.The tremie support on a working platform above water level to facilitate the placing it is built up in 1 to 3.5 m sections.The pipe must be long enough so that it reaches deeper into the bed of water, and its other end above the water level. When the freshly mixed concrete is poured with the help of the hooper, it disarranges the air and water present in the pipe and finally reaches the water bed.

During the process of concreting the tremie is continuously lifted keeping the lower end of the tube into the concrete that is already poured. One should take utmost care to maintain the continuity of concrete without breaking the seal provided by the cover of the concrete.

In this method as the concrete flow is smooth and continuous and the surface of the bed is not disturbed it will result in producing a high quality concrete slab.

Advantages of Tremie Method

During civil construction if one opts for the Tremie Method , the trick is to produce concrete below the surface of the water and then to continue to introduce new concrete just below the previously placed freshly produced concrete in continuous operation causing an upward and out flow of the heavy liquid. There are many advantages of Tremie Method; some of them are discussed below:

- It is unnecessary to de-water the caisson or cofferdam.

- It is possible to place large volumes of concrete very quickly at great depths.

- The curing conditions are perfect.

- Voids and honeycombs are eliminated provided the tremie seal is not broken.Some engineers avoid using Tremie concrete, usually because they lack experience with the technique.

Disadvantages of Tremie Method

As a coin has two sides in the same way, The Tremie method has many advantages as well as disadvantages.But in the contrary the advantage portfolio of the Tremie Method exceeds its disadvantages . However let's understand the disadvantages created by this method

- In the Tremie Method It is necessary to use a high slump, 7 to 8 inches, since it is not practical to vibrate tremie concrete.

- In many circumstances it is difficult or impossible to inspect the results of the job

- The quality and strength of Tremie cannot be analysed especially at the outer edges of the job unless the work is produced by an experienced workman under supervision and control of the Project Engineer.

- For safety measures it is always advisable to add extra cement to the Tremie Concrete.This results in increased costs and greater internal heat development. However, heat development is generally dissipated fairly quickly because of the temperature of the water above the concrete.

The Final Word

Tremie Method is one of special type of underwater concreting which produces high performance concrete used in present, past and in the foreseeable future as long as there is need to construct bridges, with foundations in soil with high water levels, and almost all off- and on-shore structures.The Tremie method has developed dramatically in the recent years so that the mix can be proportioned to ensure high fluidity as well as high resistance of washout and segregation.